Advantages

High strength

Prints are dimensionally stable

Dimensional stability along with repeatability

Ideal Applications

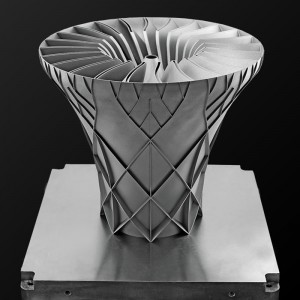

Aerospace

Household electronic

Automobile

Medical assistance

Art and craft

Architecture

Technical Data-sheet

| Category | Measurement | Value | Method |

| General properties | Powder melting point (DSC) | 186° C/367° F | ASTM D3418 |

| Particle size | 58 μm | ASTM D3451 | |

| Bulk density of powder | 0.48 g/cm3/0.017 lb/in3 | ASTM D1895 | |

| Density of parts | 1.3 g/cm3/0.047 lb/in3 | ASTM D792 | |

| Mechanical properties | Tensile strength, max load7, XY, XZ, YX, YZ | 30 MPa/4351 psi | ASTM D638 |

| Tensile strength, max load7, ZX, XY | 30 MPa/4351 psi | ASTM D638 | |

| Tensile modulus7, XY, XZ, YX, YZ | 2500 MPa/363 ksi | ASTM D638 | |

| Tensile modulus7, ZX, XY | 2700 MPa/392 ksi | ASTM D638 | |

| Elongation at break7, XY, XZ, YX, YZ | 10% | ASTM D638 | |

| Elongation at break7, ZX, XY | 10% | ASTM D638 | |

| Flexural strength (@ 5%),8 XY, XZ, YX, YZ | 57.5 MPa/8340 psi | ASTM D790 | |

| Flexural strength (@ 5%),8 ZX, XY | 65 MPa/9427 psi | ASTM D790 | |

| Flexural modulus,8 XY, XZ, YX, YZ | 2400 MPa/348 ksi | ASTM D790 | |

| Flexural modulus,8 ZX, XY | 2700 MPa/392 ksi | ASTM D790 | |

| Izod impact notched (@ 3.2 mm, 23ºC), XY, XZ, YX, YZ, ZX, ZY | 3 KJ/m2 | ASTM D256 Test Method A | |

| Shore Hardness D, XY, XZ, YX, YZ, ZX, ZY | 82 | ASTM D2240 | |

| Thermal properties | Heat deflection temperature (@ 0.45 MPa, 66 psi), XY, XZ, YX, YZ | 174° C/345° F | ASTM D648 Test Method A |

| Heat deflection temperature (@ 0.45 MPa, 66 psi), ZX, XY | 175° C/347° F | ASTM D648 Test Method A | |

| Heat deflection temperature (@ 1.82 MPa, 264 psi), XY, XZ, YX, YZ | 114° C/237° F | ASTM D648 Test Method A | |

| Heat deflection temperature (@ 1.82 MPa, 264 psi), ZX, XY | 120° C/248° F | ASTM D648 Test Method A | |

| Reusability | Minimum refresh ratio for stable performance | 30% | |

| Recommended environmental conditions | Recommended relative humidity | 50-70% RH | |

| Certifications | UL 94, UL 746A, RoHS,9 REACH, PAHs |